In this expert-written article, you can learn about the differences and similarities of Advanced solid Bioenergy. In particular, we will take a look at the comparison of Torrefaction vs. Steam exploded technology.

If you are interested or involved in a Biomass project, we at Rinke-Engineering are the right partner to talk to for professional advice regarding the planning, management, and implementation of Biomass Energy projectss like Biomass Heating Plants and Pellet Production Plants. Contact us now!

What is Advanced solid Bioenergy?

Solid bioenergy comes from solid biomass fiber and is the opposite off liquid bioenergy. Liquid bioenergy are all liquids produced from plants, for example oil fruits or juices, as a product of the forest and agriculture production. The solid part of plants is used for energy already for a long time. Wood as biomass source is the oldest energy source humans are using. We are now going to call any form of upgraded pure solid bioenergy “advanced biofuel”. The advantage starts with upgrading the density to a very solid product, like wood pellets. After drying, the product comes down to a very low water content and high energy content. Pressing the fiber increases energy density. We must change the composite of the ingredients of the solid bioenergy before we have a “More Advanced Solid Bioenergy” (MASB).

This More Advanced Solid Bioenergy is used in existing energy conversion systems, like power plants from the electricity producer. MASB`s must have the same properties as coal to be used. There are two different general process technologies which can be named and divided:

- torrefaction technology

- steam exploded technology

The final product from both technologies look pretty much the same from the outside. But the torrefaction technology gives more black and dark pellets as a product. The steam exploded technology produces mostly dark brown pellet with very interesting behaviors.

To replace coal in a coal fired power plant the following characteristics needs to be fulfilled:

follow characteristics needs to be fullfilled

Grindability

The technology of handling the new fuel needs to be able to also handle the existing fuel (coal) in parallel. This is needed as the most plants are not converted 100% to a dedicated biomass plant. This means they are also using coal and do use biomass as co- firing. This requires that the product needs to be in the same physical dimension as coal. As the most power plants are using coal dust to be blown in the furnace the maximum diameter of any particle burnt with coal needs to be smaller than 1 millimeter. The cool will be milled in existing coal mills and the new fuel must have the same grindability to be milled to the same size using the same milling system.

Grindability is a characteristic which must be fulfilled.

Water resistance

At coal power plants the fuel is very often stored outside. Weather conditions outside can be very wet during certain time of the year. Therefore, it is necessary to also have the new product (torrefied or steam exploded pellet) stored outside to use the same area and technology. A normal white pellet will turn into wet sawdust when it has contact to water. Therefore, the treatment of torrefying or steam exploding needs to end in a product which is hydrophobic and is therefore capable to store also in wet areas.

Water resistance is a characteristic which must be fulfilled.

Transport density

Energy transport around the world comes with a cost. Therefore, it is needed that the energy content of any cubic meter which is transported needs to be as high as possible. As black cool is a high-density product with an energy content of around 30MJ/kg at 830g/l (dry), a cubic meter contains 25GJ. White wood pellets have around 18.5MJ/kg at 600g/l (dry), a cubic meter contains 12GJ. With torrefied pellets or with steam exploded pellets this can be increased significantly.

Energy density of Biomass for Transport is a characteristic which must be as high as possible.

Cost efficiency

Energy conversion comes with costs; this means that the energy producer needs to find the cheapest energy source to produce their product electricity as cheap as possible. Climate change forced the politicians to set circumstances where the electricity producer needs to fulfill the reduction of CO2 emission from nonrenewable energy sources. To use solid sustainable and renewable fuel in a coal fired power plant, the energy producer can convert the technology of grinding and storing to the white pellet energy source like DRAX (biggest English energy producer) did in the past. Doing so, a huge investment of storage and handling equipment is needed. Using advanced biofuel as torrefaction or steam exploded pellets means that there is no investment in technology needed before using renewable fuels as a co-firing or as dedicated biomass. The energy price itself is then the only cost comparison when buying the fuel. The price of biomass feed it in the energy plant is limited to the fee any energy producer needs to pay if not burning the required amount of CO2 neutral energy.

Cost efficiency is a characteristic which must be compatible with the circumstance of using.

The described minimum requirements on advanced biofuel needs to be fulfilled before the next generation of biofuel will meet all circumstances. Until now steam exploded pellets meet all the requirements in the above description and are also already used in huge power plants for coal firing and as dedicated biomass fuel. We see that this technology will have a great future and we had the luxury of already helping the market leader to install his first industrial size steam exploded pellet production. We hope also that this success will continue.

What are the steps to getting black Pellets?

Explaining the thermal conversion of biomass is talking first about the chemicals and physics. As biomass is stored carbon, all conversion of biomass to any other form of energy will go the same path.

- Before we can start to gain the energy from solid biomass, we need to reduce the water content. The water content is hindering the carbon and other ingredients of biomass to be oxidized. The amount of energy needed to fulfill this first step comes with the physics of evaporating water. The only difference for using different systems for drying is the energy source for drying itself and the temperature level you like to dry with. This step of drying is the most energy consuming step to make biomass available for energy conversion. Directly used biomes will dry in the first part of the furnace before it starts burning, this energy can be recovered by condensing the flue gases and getting the energy gained back. Trying to produce a product with a higher energy value is always combining a drying process to the upgrading of biomass. After drying the biomass, the next step of energy conversion starts when you are putting more energy to those biomasses.

- In the early beginning of the thermal conversion all volatile components will pushed out buy an ignition heat source. This ignition heat source can be generated by the biomass itself, due to self-heating processes. They also can be a heat source from outside by meaning of using a match to light up your fire. In this very early step, the very volatile components will catch up fire easily and will energize the solid or liquid state of aggregation two a gasified state of aggregation. This first step is called gasification of biomass or pyrolysis. This process is often described as a separate technology in some reports, but it is only the early first step of burning biomass without sufficient oxygen around.

- If enough oxygen is around this gas from biomass will light up very easy and will support more energy to the solid or liquid state of aggregation for the remaining biomass. In the second step the oxygen surrounding the fire will ensure, that all available carbon components will be oxidized to CO2 completely. This oxidization is a release of the remaining energy for all biomass and can be used in different heat and power plants. The greatest advantage of using biomass is the fact, that biomass has not only stored carbon in a pure form. It comes in a biological form with different ingredients specified by the species of plant and the type of biomass.

What is the Torrefaction process?

At the torrefaction process the first step is drying the biomass down to very low level of water content. This need to be fulfilled to go through the torrefaction process. The torrefaction process itself is the same what we do when we produce coffee. It means that we are putting energy to the dry biomass from outside. All volatiles are forced to evaporate, the loss of those volatiles is driven by the temperature and time of this process.

Torrefaction refers to the thermal treatment of biomass without access to air, which leads to pyrolytic decomposition and drying. The process is carried out at 250 ° C to 300 ° C, a relatively low temperature for pyrolysis. To learn more about the torrefaction itself we’ll recommend to go to the home pages from different companies around the world offering this type of technology: (https://publicaties.ecn.nl/PdfFetch.aspx?nr=ECN-L–12-026)

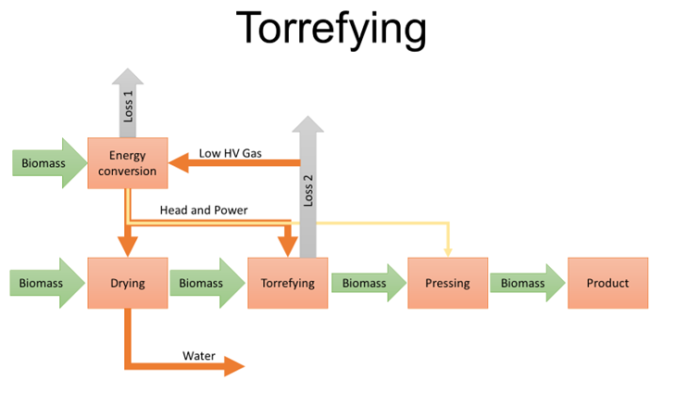

The above general description of a torrefaction process is showing that you need two flows of biomass to the process. First you need the raw material for the process to upgrade it to the needed advanced biofuel and secondly you need the energy for the drying and treatment process. During the raw material and energy inputs to the system you will have losses during each process.

Torrefaction process: Treatment Loss 1

The first loss of energy comes from the energy conversion of biomass. This energy loss can be reduced using a higher efficiency energy conversion system which should run to produce electricity and heat for the process with a maximum of 15% losses.

Torrefaction process: Treatment Loss 2

The second loss comes from the torrefying process itself and depends on the content of volatile compounds in the raw material biomass. Putting heat to the torrefaction process will force the volatiles to evaporate. This low energy gas can be used in the furnace to generate heat but in any case, it needs to be treated before it can be released to the environment. This loss of gases reduced by the amount of energy be used in the energy conversion, will be around 10% up to 25% of the treated biomass.

What is the Product after the Torrefaction Process?

The treatment of the biomass to produce torrefied material starts after the drying process. Gas produced by the treatment process can be used as low energy content gas in a furnace, but these gases are still not used 100%. The losses of the treatment are energy losses. The black pellets which can be produced out of the treated biomass fiber can be burned directly on a great firing system or can be milled down to fuel a powder burner. Tests on the torrefied pellets showed that the resistance against water is not as stable as expected. The fiber itself is not accumulating water anymore after the treatment but the durability of these black pellets is getting lower when water is added.

What is the Steam Exploded process?

The conversion whit steam as energy source to the treatment process opens the possibility to use the Volatiles and Energy in a recovery system. The energy recovery will be used for the drying process and condensed Liquid volatiles can be sold a second product. The process is owned by the developer and only exclusively sold to their clients. To use this technology please contact: https://www.arbaflame.no/

Steam Exploded process: Treatment Loss 1

The first loss of energy comes from the energy conversion of biomass for energy production. This energy loss can be reduced using a higher efficiency Energy conversion system which should run to produce electricity and heat for the process with a maximum of 15% losses. The amount does not differ to losses during torrefaction.

Steam Exploded process: Treatment Loss 2

The second loss comes from the steam exploded process itself and from the post drying and depends on the content of volatile compounds in the raw material biomass. The steam for the steam exploded pellet process is produced by the boiler which runs a CHP plant (Loss 1). The steam is doing the treatment process and will be condensed after. As the treatment of the biomass is done when the product is still semi wet, the drying process will also produce evaporated water which can be condensed to gain any energy form. These two condensing processes are producing enough energy to run the dryer. It will also produce a condensate which contains very interesting chemical ingredients which can be sold as a second product to the industry with high value. The only loss we have, comes from the non-condensable gases which are also used in the energy conversion system with the efficiency of the furnace and CHP plant (Loss 1).

For more information to the above please visit: https://www.arbaflame.no/ , the marked leader of this process.

What is the Product after the Steam Exploded Process?

Steam exploded pellets are very close to the behavior of coal. This describes not in full the unique physics of the product. Energy content can be very high and meet the expectation of the clients to reduce transport costs. The water resistance y is proven by different clients around the world running a power station and are documented already. The durability is also very stable, and the number of fines is very low. On top of all these beautiful characteristics the grindability is very high and meets the expectation, to be milled in a coal mill down to the needed particle size. Besides this solid product from the process, there is also a liquid which is produced from the chemicals out of the condensate. The value of the liquid is very high, as it is a needed raw material for the chemical industry. This second product is also increasing the revenue from the steam exploded pellet process in combination whit the stripping unit to get the chemicals separated.

Conclusion

The following matrix shows the pros and cons for both systems:

| Torrefied Pellets | Steam Exploded Pellets | |

| Grindability in coal mill | ++ | ++ |

| Water resistance to store outside | – | ++ |

| Transport density to lower cost | ++ | ++ |

| Status of process development | + | ++ |

| Product revenue | + | ++ |

Biomass is everywhere! Look outside and get an idea of using it for a special product or energy source to the existing circle of CO2 and lower the pressure on our climate!

Talking about efficiency will be the key player of finding the best home for the high-quality industrial pellets and biomass in total for all uses. All renewable energy sources will need to find best efficient use to be used is a long run.

Explaining all this to you gives you a small overview about the key points of using bioenergy and explained hopefully the advantages of bioenergy and biomass energy to all human being. In the future it is more than important that not only the production of renewable energy, like wind and solar will increase, we also need to implement in our energy system an easy storable renewable energy like biomass. We are your partner to gain this target. Let’s do it together!